| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : XWH

Model Number : D(N)B-100,D(N)B-160, D(N)B-200, D(N)B-250

Certification : CE, RoHs

Place of Origin : China

MOQ : 1

Price : USD24000-USD30000

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 50 sets/month

Delivery Time : 30 working days

Packaging Details : Wooden Case

Product name : Resistance Welders Projection Stainless Steel Shock Absorber Welding Machine

Application : Shock Absorber Welding

Function : Metal Spot Welding Machine

Machine type : Resistance Spot Projection Welding

Keyword : Stationary Spot And Projection Welding Machine

Welding Material : Projection Welding Machine

Feature : Pedal Point Welding Machine

Warranty : 12 months Guarantee

After Warranty Service : Video technical support, Online support and Spare parts

After-sales Service Provided : Free spare parts, Field installation, commissioning and training

Resistance Spot Welders Projection Stainless Steel Shock Absorber Welding Machine

Product Introduction:

The projection welding machine is designed for welding shock absorber oil storage cylinder convex ring.Mainly composed of main frame, pneumatic transmission mechanism, horizontal welding mechanism, support components, secondary circuit, welding transformer, welding controller, water and gas circuit system and other components.

Welding Advantages:

1.Within a unit length, the heating time is short and the heat is concentrated, resulting in a small heat affected zone and minimal deformation and stress. Therefore, it is usually not necessary to arrange correction and heat treatment processes after welding.

2.No need for filler metals such as welding wires and rods, as well as welding consumables such as chlorine, ethylene, hydrogen, etc., resulting in low welding costs.

3.Simple operation, easy to achieve mechanization and automation, low requirements for worker proficiency, and low labor intensity.

4.High productivity, low noise, and no harmful gases.

5.Can be used for convex welding of hoop rings.

Technical Parameters:

| Items Models | DN(B)-100 | DN(B)-160 | DN(B)-200 | DN(B)-250 |

| Rated power (KVA) | 100 | 160 | 200 | 250 |

| Power input(V) | 3φAC 380V | 3φAC 380V | 3φAC 380V | 3φAC 380V |

| Max. short circuit current (KA) | 30 | 35 | 40 | 45 |

| Duty cycle(%) | 50 | 50 | 50 | 50 |

| Max. force(N) | 6000 | 6000 | 10000 | 15000 |

| Electrode length( MM) | 450 | 450 | 450 | 500 |

| Working stroke( MM) | 80 | 80 | 80 | 80 |

| Cooling consumption(L/min) | 20 | 20 | 20 | 20 |

| Max. welding capacity(MM) | 3.0+3.0 | 4.0+4.0 | 5.0+5.0 | 6.0+6.0 |

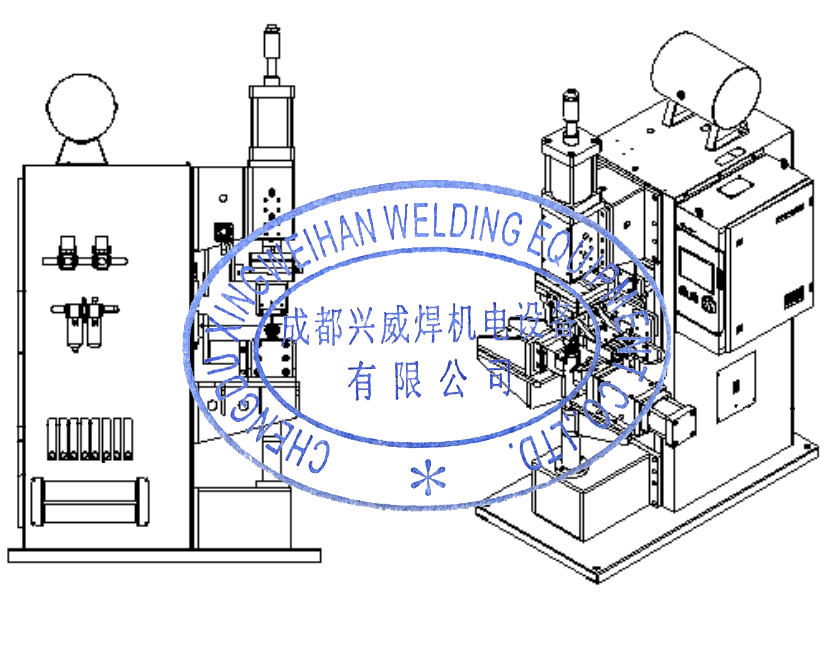

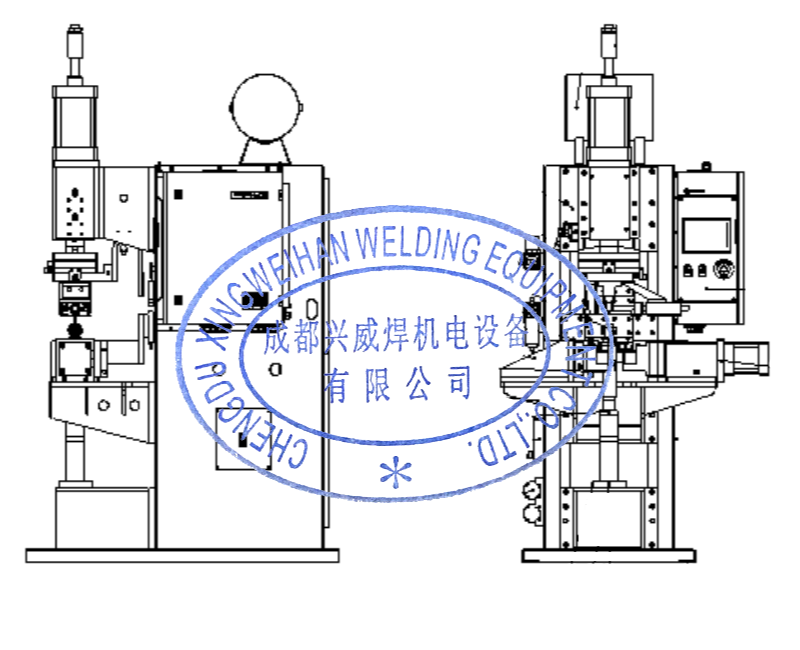

General Structures:

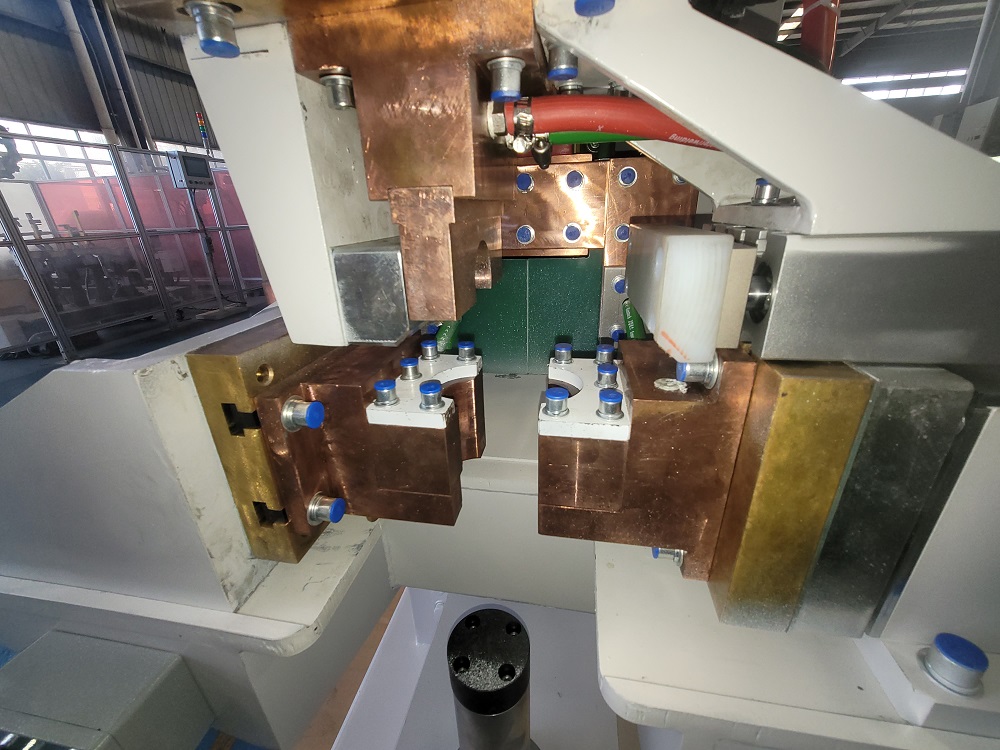

Detailed Images:

The Upper Electrode: The upper electrode is pressurized with an auxiliary cylinder, making stroke adjustment convenient and precise, allowing for continuous adjustment of the workpiece operation stroke.

Gas Storage Tank: The spare dedicated gas storage tank for welding machines is beneficial in reducing welding pressure fluctuations and ensuring stable welding force.

Production Line:

Application:

FAQ:

|

|

Resistance Spot Welders Projection Stainless Steel Shock Absorber Welding Machine Images |